Mixer Suppliers share with you the maintenance procedures of the mixer

First,Safety procedures

1、Mixer transmission chain protection cover should be intact, to prevent personal injury from touching the chain at work.

2, the motor base fastening bolts should be regularly checked, the base should have sufficient steel to prevent the chain from jumping or falling off due to a loose base, resulting in transmission failure.

3、When inspecting, repairing and maintaining the machine, the power must be cut off and the sign must be hung.

4、It is strictly forbidden to put hands or other tools into the machine during the operation of the machine.

5、Only after the Mixer is completely stopped, the machine can be cleaned and inspected.

6、Cables and wires should have protective sleeves.

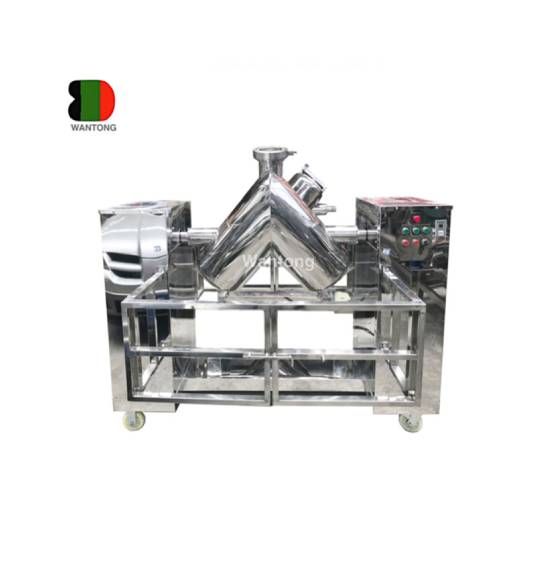

V-type mixer

Second, maintenance procedures

1、During operation, check at least once a shift whether the compressed air pipeline is leaking, and discharge water in the oil-water separation triplex once.

2、Check once a week whether the unloading door is leaking, whether the seal is broken, and whether the unloading rod mechanism is in the dead position when closing the door.

3、Clean up the residual materials attached to the inner wall of buffer hopper once a week.

4、Brush the transmission chain and sprocket with diesel oil once a month, and brush the chain and sprocket with new oil.

5、Clean the oil nozzle once a month, while cleaning the inner wall of the mixer and the residual attached material on the cover.

6, once a month to determine the coefficient of variation of the mixer outlet and finished packing mouth, the coefficient of variation should be selected to determine the shortest mixing time products.

Third, maintenance procedures

minor repairs

Mixer minor repair once every six months, including the following.

1, check the motor junction box wire connection is loose.

2、Clean up the residual material attached to the inner wall of the mixer and buffer hopper.

3、Clean up the oil and water separation triplex to ensure the smooth flow of air.

4、Check the wear of the pin of each hinge connection point of the unloading linkage mechanism, replace the pin with serious wear to ensure the reliability and smoothness of the operation of the linkage mechanism.

5、Replace the sealing strip of the discharge door, check the reliability of the limit stroke of the switch door and adjust its position to ensure the sealing of the discharge door.

6、Check the transmission chain tightness and motor seat fastening, adjust the chain tensioning wheel or motor base to keep the chain with proper tensioning.

7、Replace the reducer grease.

repair

Mixer repair is carried out once a year, including the following.

1, all the contents of the minor repair.

2, clean up the rotor wear and rotor clearance between the guest, repair or replace the badly worn screw belt or paddle, adjust the clearance between the rotor and the shell to the allowable range.

3、Clean the main bearing and bearing seat, check their wear and tear, replace them if necessary, and fill the bearings with lubricant.

4、Check the wear of the cylinder and replace the parts with serious wear.

5、Check the compressed air pipeline, especially check the aging of the hose, and replace it if necessary.

6、Disassemble and clean the reducer, check the wear of the parts, replace the worn parts if necessary, and grease the reducer at the same time.

7、Check the wear of transmission chain and sprocket, and replace them if necessary.

8、Check the wear of the motor bearing and grease the motor bearing.

The company also provides Double Cone Mixer and V-type mixer, if you need, please feel free to contact us!

Copyright © Jiangyin Wantong Pharmaceutical & Chemical Machinery Co., Ltd. All Rights Reserved