This equipment is a new equipment of our company recently developed. It has the advantages of automatic unloading, the efficiency is 2-3 times more than YK - 160 swing granulator, also meet the GMP standard. It is one of the ideal granulating equipment. Simple structure, easy to operate, easy to move. Automatic discharge, to make up for the shortcomings of the old manual unloading. Continuous operation. Suitable for semi dry powder state and with viscous material, medicinal granules, solid beverage, chicken and other foods.

Products Details

1.Main Use:

This equipment is a new equipment of our company recently developed. It has the advantages of automatic unloading, the efficiency is 2-3 times more than YK - 160 swing granulator, also meet the GMP standard. It is one of the ideal granulating equipment. Simple structure, easy to operate, easy to move. Automatic discharge, to make up for the shortcomings of the old manual unloading. Continuous operation. Suitable for semi dry powder state and with viscous material, medicinal granules, solid beverage, chicken and other foods.

2.Working principle& Structure:

Working Principle:

Through mechanical transmission make grinding blade and pressure material leaf as opposite spin, pressure material leaf's certain Angle make the material feeding into the grinding blade, a ruler to run on the knife large Angle spiral leaf inner material into a sieve, then the material be extruded into particles from screen hole, through the material blade.

Structure:

1)Hopper and granulating device's structure is designed according to installation, cleaning, useing principle. The component contact with materials all adopt stainless steel, to guarantee the products' clean.

2)Particles manufacture parts are completely sealed, to prevent lube oil sneak into raw materials.

3)Sieve net clip pipe is used to clamping shaiwang, to ensure that sieve clingy the rotating drum and not loose.

4)The user can choose corresponding sieve according to the products demands, to produce various specifications particles.

3.Technical Data:

| TYPE/ITEM | ZLG-150 | ZLG-250 | ZLG-300 | ZLG-500 |

| Power(kw) | 3 | 5.5 | 7.5 | 18.5 |

| Cylinder diameter(mm) | 150 | 250 | 300 | 500 |

| Capacity(kg/h) | 30-100 | 50-300 | 100-500 | 1000-1500 |

| Granule diameter(mm) | φ1.2-φ3 | |||

| Speed(r/min) | 60(can add frequency converter) | 50(can add frequency converter) | 36(can add frequency converter) | 36(can add frequency converter) |

| Overall size(mm) | 700×400×700 | 1200×700×1100 | 1350×800×1200 | 2500×1500×2000 |

| Weight (kg) | 200 | 400 | 600 | 1000 |

Note: only for reference, special feedstock has special data.

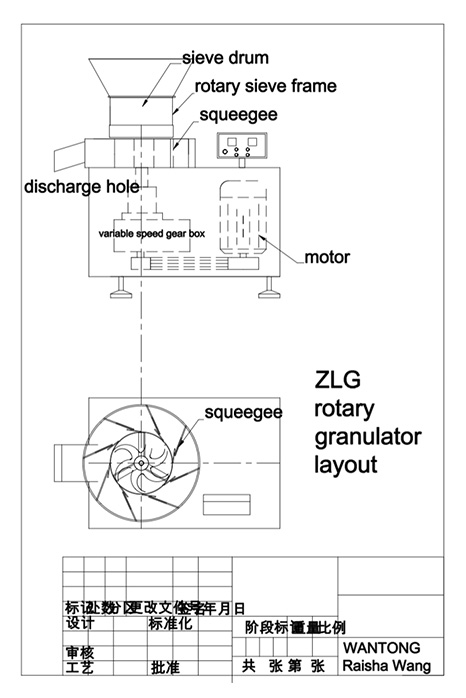

1.CONFIGURATION & LAYOUT

ZLG Rotary granulator Equipment configuration

| NO. | ITEM | SPECIFICATION | Qty. | supplier |

| 1 | sealing plate | SUS304 s=1.2mm | SELF | |

| 2 | Blade material | SUS304 | 1 | WUXI |

| 3 | Press plate | SUS304 | 1 | SELF |

| 4 | Reducer box | customized | 1 | changzhou |

| 5 | motor | 1 | WUXI | |

| 6 | Granulating sieve drum assembly | SUS304 | 1 | SELF |

| 7 | Transmission belt | B type | 3 | WUXI |

| 8 | Pelleting scraper | SUS304 | 1 | SELF |

| 9 | Discharge hole | SUS304 | 1 | SELF |

| 10 | electric | 1 | DELIXI |

ZLG Rotary granulator layout:

Copyright © Jiangyin Wantong Pharmaceutical & Chemical Machinery Co., Ltd. All Rights Reserved